5 Types of Forklift Brake System Mechanisms

Forklifts play a crucial role in warehouses, distribution centers, and industrial facilities, making efficiency and safety top priorities. One of the most essential safety components of a forklift is its braking system, which ensures operators can stop or control the vehicle effectively. Various forklift brake mechanisms are designed to suit different types of forklifts and working environments. This article explores the key types of forklift braking systems and their unique functions.

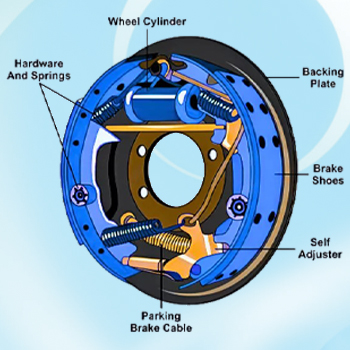

1- Drum Brakes

Drum brakes are one of the most traditional braking systems used in forklifts. They operate through brake shoes that press against the inside of a rotating drum, creating friction that slows down the vehicle. These brakes are commonly found in older models and low-speed forklifts.

Advantages

- Cost-effective compared to other systems.

- Durable with proper maintenance.

- Works efficiently for lower speeds and lighter loads.

Disadvantages

- Generates significant heat, leading to wear over time.

- Requires regular adjustment to maintain effectiveness.

- Can collect dust and debris, affecting braking performance.

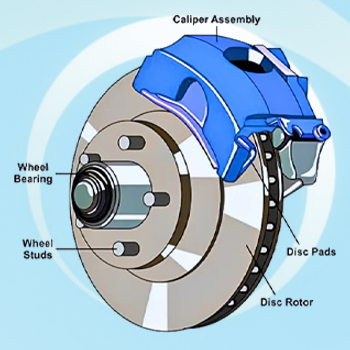

2- Disc Brakes

Disc brakes function by pressing brake pads against a rotating disc (or rotor), creating the necessary friction to stop or slow down the forklift. These brakes are widely used in modern forklifts due to their reliable stopping power.

Advantages

- Provides superior stopping ability, even under heavy loads.

- Dissipates heat better than drum brakes, preventing brake fade.

- Requires less maintenance and adjustment.

Disadvantages

- Higher initial cost compared to drum brakes.

- May wear faster under continuous heavy use.

- Susceptible to contamination from oils and grease.

3- Regenerative Braking

Regenerative braking systems are commonly found in electric forklifts. This system works by converting kinetic energy into electrical energy, which is then fed back into the battery rather than being lost as heat. The braking mechanism slows down the forklift while simultaneously recharging the battery.

Advantages

- Enhances energy efficiency by extending battery life.

- Reduces wear on mechanical brake components.

- Provides smooth deceleration, improving operator control.

Disadvantages

- Does not replace traditional brakes and must be used alongside other braking mechanisms.

- Less effective at sudden or emergency stops.

- Works best at lower speeds, limiting its impact in fast-paced environments.

4- Wet Disc Brakes

Wet disc brakes differ from standard disc brakes in that they are enclosed in a fluid-filled chamber. This design reduces friction and enhances durability, making them ideal for heavy-duty forklifts operating in demanding environments.

Advantages

- Extended lifespan due to reduced wear.

- Performs well in extreme conditions like high temperatures or frequent stops.

- Requires minimal maintenance compared to traditional braking systems.

Disadvantages

- More expensive to install and replace.

- Complexity of the system makes repairs more challenging.

- Requires specialized fluids to maintain optimal performance.

5- Spring-Applied Hydraulic Release (SAHR) Brakes

SAHR brakes are automatic braking systems that engage when hydraulic pressure is lost. These brakes are often found in high-capacity forklifts and ensure safety in case of system failure.

Advantages

- Provides fail-safe stopping capability in emergencies.

- Ideal for steep inclines and heavy loads.

- Minimizes human error by engaging automatically.

Disadvantages

- Complex system requiring specialized maintenance.

- Higher upfront cost.

- Can be difficult to troubleshoot if hydraulic pressure fluctuates.

Conclusion

Selecting the right forklift brake mechanism for a forklift depends on the operating environment, load capacity, and specific safety requirements. Whether using traditional drum brakes, advanced wet disc systems, or energy-efficient regenerative braking, each system has its advantages and trade-offs. Proper maintenance and regular inspections are key to ensuring optimal braking performance and preventing workplace accidents. By understanding the different types of forklift braking mechanisms, businesses can improve both operational efficiency and safety standards.

At Trust Lift Trucks, we specialize in on-site forklift brake repair services for all forklift brands and models. Whether your forklift engine is powered by PSI, Kubota, GM, Nissan, Mazda, or any other engine type, our skilled technicians are equipped to diagnose and resolve any issues efficiently. We also provide both propane and electric forklifts fully refurbished for your warehouse. We are just a call away from you in Toronto and GTA.